Introduction to Live centers

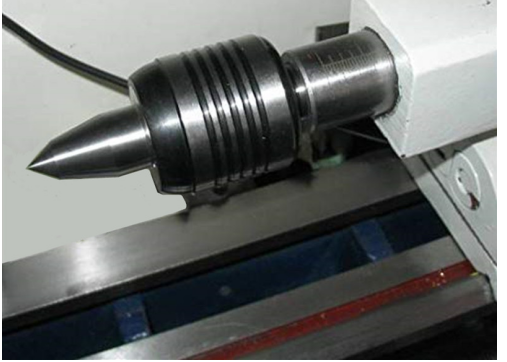

The live center is a kind of machine tool accessories, which plays a very important role in the machine tool accessories, and is also very important for the processing of the workpiece. When we usually use the live center, we often encounter when using two live center to install the workpiece at the same time. Compared with using one, it is more difficult, so there are many things to pay attention to.

The live center is mainly used for machining shaft parts on the lathe. With the help of the center hole positioning, the workpiece can obtain high dimensional accuracy. Because of frequent use, the tool scratches the center, the 60° cone tip is broken, and the surface is worn. Affecting the use or even scrapping it will cause economic losses.

However, as long as the bearing in the top is not damaged, the 60° conical surface can be ground on the cylindrical grinder, so that the live center can continue to be used normally. The conventional method is used for clamping. Because the machining datum does not coincide with the top working datum, the precision of the machined top is relatively low. After many tests

In conclusion, certain measures should be taken in terms of top clamping, live center rotation, auxiliary devices, etc., to process qualified products.

The difference between the fixed top and the rotary top and the disassembly method

Alloy fixed tops and live center are the two major categories of tops: fixed tops have strong bearing capacity and can process objects finely, but easily cause damage to internal bearings;live center are inferior in machining accuracy and acceptance. Fixed top, but has strong stability.

Once there is a problem in the use of the top, it must be replaced in time, and the staff mainly replaces the internal bearings of the top.

The top is divided into two types: fixed top and movable top. The top is mainly composed of a thimble, a clamping device, a housing, a fixed pin, a bearing and a mandrel. One end of the tip can top the center hole or the inner hole of the pipe material, and the other end can be a spherical or conical part on the top surface, and the tip is fixed by a clamping device. When the part does not allow or cannot be punched with a center hole, the clamping device can be used to directly clamp the turning. The shell and the mandrel are drilled with pin holes, and the fixed pins are inserted or removed to complete the dual use of the top. The center can also be used for drilling, setting and reaming of workpieces.

[The difference between the fixed top and the live centers]

1. The fixed top has the advantages of simple structure, high precision and strong bearing capacity, and is mostly used for reverse cutting processing with high positioning accuracy requirements. With a dead center, the roundness of the processed parts is high, but the top force is large, and the center hole is easily scorched.

2. Use the live center to prevent the fixed top from wear, ablation, loss of accuracy or damage. The needle roller bearing with long inclination is selected, the rigidity of the three-point support arrangement structure is strengthened, and the stability is good. However, due to the increase of parts, the accuracy and bearing capacity are not as good as the former, and they are mostly used in high-speed, low-precision reverse machining.

【Top disassembly method】

In the process of using the live center, if there is a problem with the top and it needs to be disassembled, the first thing is to find the bearing on the live center and cap it. Some people may not know where the bearing cap is. The part with two small holes in the head is the top cap. Then use something to pierce the small hole and rotate it gently so that the bearing and cap can be taken out, then remove the screw at the rear of the tapered sleeve end, and then use something to push the bearing out of the top shell from the rear , After replacing the deep groove bearing and the thrust bearing, the merit is complete. Reverse the order when installing.

There are certain small differences between the tops, so be careful in the selection and use of the tops. Also be careful when replacing the top internal bearing.

How to Repair a live center

When we use the live center, the phenomenon that the top is suddenly stuck and does not rotate often occurs. When the above phenomenon occurs, the machine should be stopped immediately and the cause should be checked. Check whether the problem is the bearing or the tip is damaged, and repair it reasonably and effectively according to the failure conditions of different reasons.

(1) If it is a bearing problem, remove the cover and take it out, and remove the bearing. On the three-jaw self-centering chuck, the loading head of the casting material clamps the end face of the car, and the inner hole and the center bearing are mounted on the car, and the matching clearance is controlled at 0.005~0.01mm. Prepare a chicken heart chuck (which can be placed on the top), install the chicken heart chuck on the tip and tighten it, then put it into the cast iron sleeve, put the chicken heart chuck on the jaws, and adjust the small pallet counterclockwise by 30. Turning can be done by adjusting the angle. The 60 cone can be completely car up. Remove the tip, put on a new bearing, and install it to use. This method is more troublesome.

(2) If the live center rotates normally, only the tip is damaged. In order to solve this situation, we turn a sleeve with a step and screw it on the top with two M10 socket head cap screws, then remove the lathe chuck, clean the spindle hole, and insert the top into the taper hole (if Morse’s) No. 4 tip, plus reducing sleeve). The shyness sub-table corrects the 60-cone surface, and tightens 2 M6 screws at the same time. In this way, the correction of the top is simple. When using, select the rotary top reasonably, choose the top with low precision for rough turning, and select the top with high precision for fine turning.