How to make a chuck soft Jaw, a technique that can’t be learned from the master! !

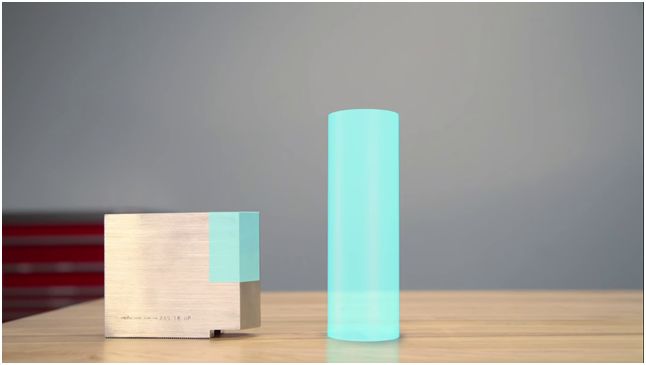

The soft Jaw can ensure the repeated positioning accuracy of the workpiece to the greatest extent, so that the center line of the workpiece can be completely coincident with the center line of the spindle, and the flat surface on the soft claw can also ensure the length of the workpiece.

The most important thing is that the soft jaw can fit the surface of the workpiece to the greatest extent, which can not only ensure the transmission of greater torque, but also avoid workpiece clamping. These advantages are unmatched by hard jaws.

The “soft” here means: good processing performance does not mean that the hardness of the workpiece must be lower than that of the workpiece (for mass production, the hardness of the soft jaw will have a great impact on the stability of processing, and the choice is higher than the hardness of the workpiece. The soft claw material will not only improve the service life of the soft claw, but also have a positive impact on the processing stability)

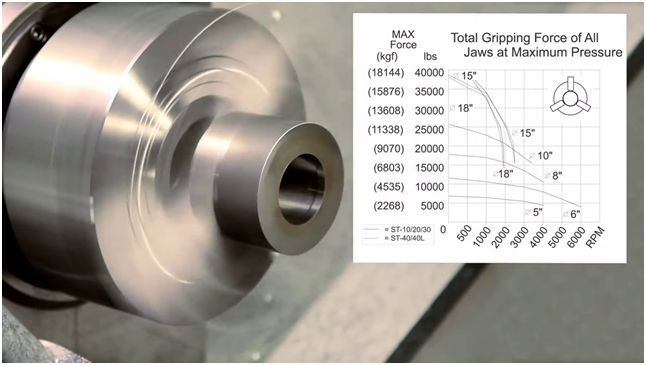

5. The influence of the diameter and rotation speed of the chuck on the clamping force

Due to the centrifugal force, the clamping force will be greatly reduced when the chuck operates at high speed. For details, please refer to the instructions on the chuck.

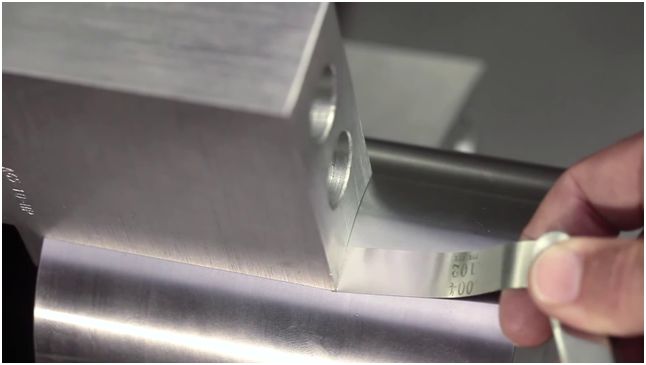

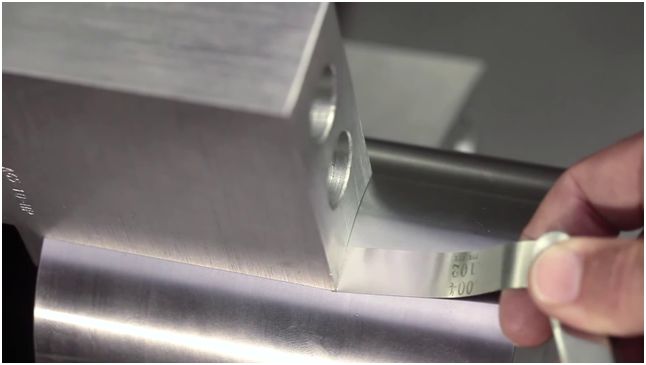

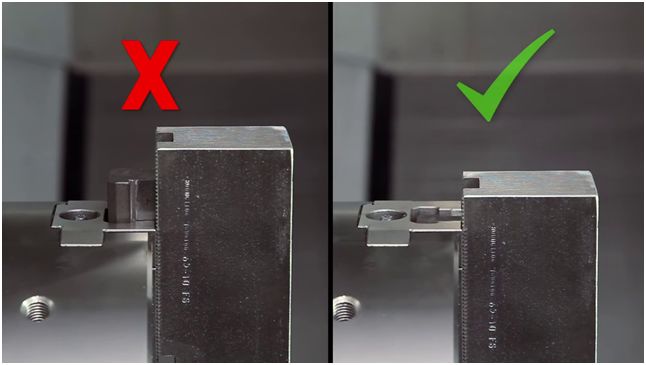

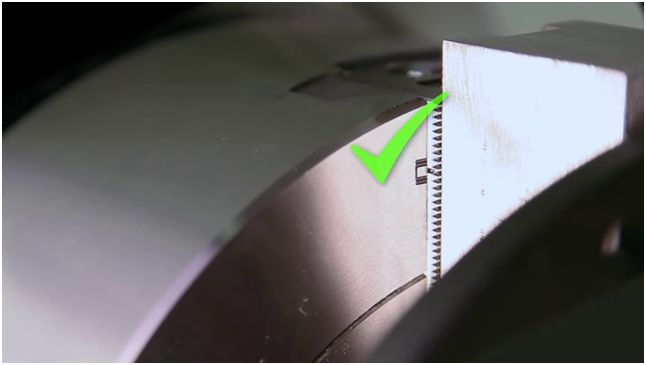

7. Add undercuts

To ensure the repeated positioning of the workpiece

In the video below, the effect of rotational speed on gripping force is illustrated through practical tests.

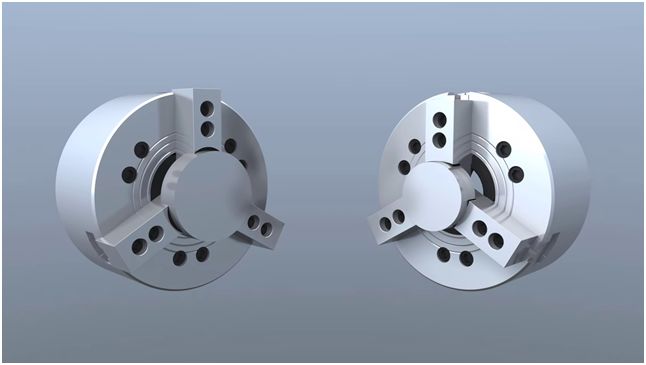

When machining thin-walled or annular workpieces, overcoming the deformation of the workpiece is the first problem to be faced. The key to choosing the type of soft jaws and the appropriate chuck pressure is.

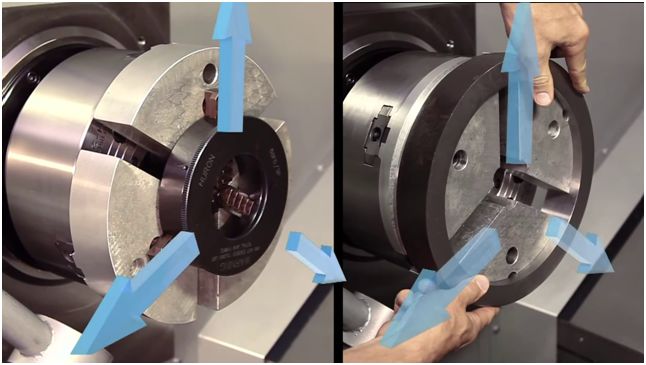

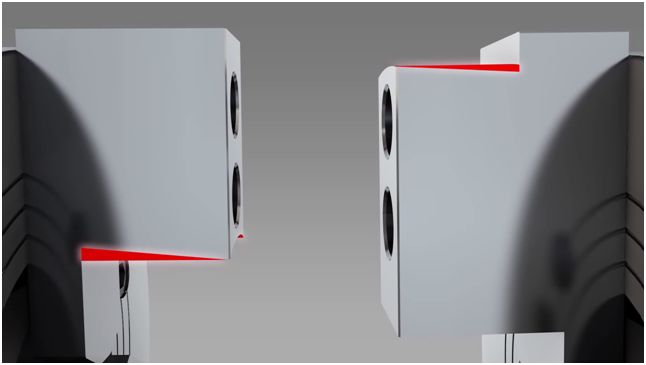

Under the same chuck pressure, the fan-shaped soft jaw has a larger contact area than the standard soft jaw, which means that the workpiece is subjected to more uniform pressure, while the standard soft jaw will have the following conditions:

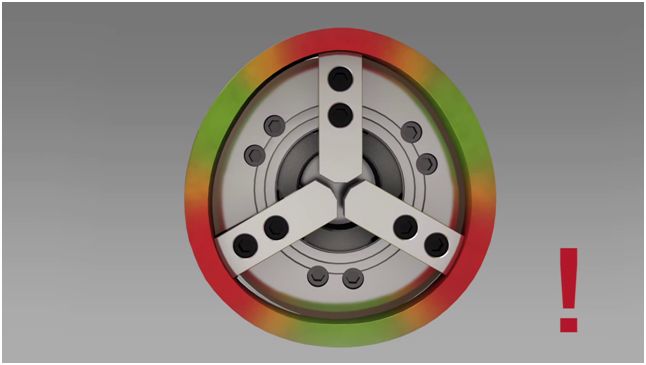

The actual situation may not be as obvious as in the picture, but you will clearly see in the video at the bottom that the deformation of the workpiece even appears dozens of times under the same conditions except for the type of soft claw. The difference, whether it is a fan-shaped soft claw or a standard soft claw, will need to be rebuilt due to excessive wear of the soft claw or the replacement of machined parts.

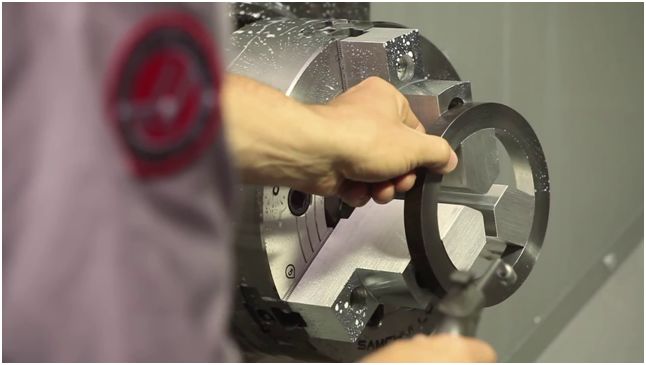

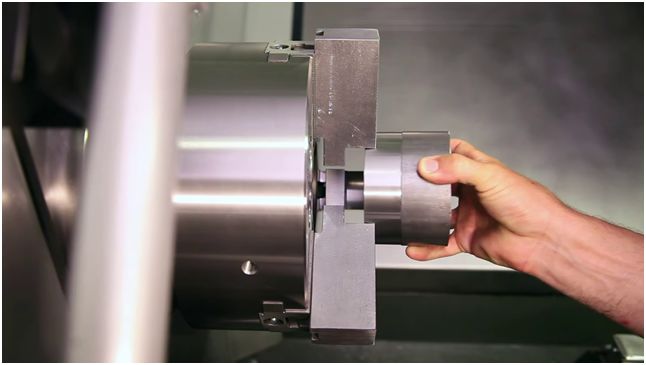

In the process of rebuilding, the soft claws to be removed should be marked and numbered first, in order to increase the use of the soft claws, and more detailed markings will also reduce the possibility of misuse.

Next comes the choice of claw trimmers:

Generally speaking, the left claw trimmer trims the inner claw, and the right trims the outer claw.