Eight kinds of thread processing methods

Common thread processing methods mainly include turning, milling, grinding, whirling, tapping, thread rolling, thread rolling and EDM. Today we will share these processing methods.

1.thread turning

Thread turning on a lathe can be done with a forming turning tool or a thread comb. Turning threads with a forming turning tool is a common method for single-piece and small batch production of threaded workpieces due to the simple tool structure; turning threads with a thread combing tool has high production efficiency, but the tool structure is complex and only suitable for medium and large batch production. Turning short thread workpieces with fine pitch.

2.thread milling

Milling with a disc or comb cutter on a thread mill. Disc milling cutters are mainly used for milling trapezoidal external threads on workpieces such as screw and worm. Comb-shaped milling cutters are used for milling internal and external common threads and tapered threads. Since they are milled with multi-blade milling cutters, the length of the working part is greater than the length of the thread being processed, and the productivity is high.

3.thread grinding

Thread grinding is mainly used to process precision threads of hardened workpieces on a thread grinding machine. According to the different cross-sectional shapes of the grinding wheel, it is divided into two types: single-line grinding wheel and multi-line grinding wheel grinding. Single-line grinding wheels are suitable for grinding precision screws, thread gauges, worms, small batches of threaded workpieces and relief grinding precision hobs. The multi-thread grinding wheel is suitable for relief grinding of taps in large batches and for grinding certain threads for fastening.

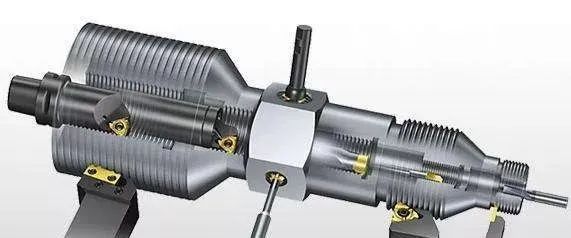

4.whirling

Whirlwind milling is a thread processing method that mills threads from a workpiece through a carbide forming tool mounted on a high-speed rotating cutter head. When whirling milling, the spindle speed of the machine tool is slow, so the machine tool has high motion accuracy and good dynamic stability, which is an advanced thread processing method.

5.Tapping thread

Tapping is to screw the tap into the pre-drilled bottom hole on the workpiece with a certain torque to process the internal thread. Threading is to cut the external thread on the bar (or pipe) workpiece with a die. The machining accuracy of tapping or threading depends on the accuracy of the tap or die

6.thread rolling

Thread rolling is to stagger two thread rolling plates with a 1/2 thread pitch relative to each other, the static plate is fixed, and the moving plate performs a reciprocating linear motion parallel to the static plate. When the workpiece is sent between the two plates, the moving plate moves forward and rubs the workpiece to plastically deform its surface into a thread.

7.rolling

There are three types of thread rolling: radial thread rolling, tangential thread rolling and rolling head thread rolling.

Radial thread rolling is two (or three) thread rolling wheels with thread profile installed on mutually parallel shafts, the workpiece is placed on the support between the two wheels, and the two wheels rotate at the same speed in the same direction. Also make radial feed movement.

Tangential thread rolling is also called planetary thread rolling. The rolling tool consists of a rotating central thread rolling wheel and three fixed arc wire plates. During thread rolling, the workpiece can be continuously fed, so the productivity is higher than that of thread rolling and radial thread 8.rolling

The thread rolling of the rolling head is carried out on an automatic lathe and is generally used to process short threads on the workpiece. During thread rolling, the workpiece rotates, and the rolling head feeds axially to roll the workpiece out of the thread.

EDM

Compared with the machining method, EDM has the same order, and both need to make a bottom hole first, and the diameter of the bottom hole should be determined according to the working conditions. There are two methods for EDM threads, namely the thread electrode rotary machining method and the shaking machining method.

During machining by the screw electrode rotary machining method, discharge is started from the electrode end and machining is performed in the circumferential direction. Since electrode loss is concentrated at the end of the thread, it is necessary to machine deeper to obtain effective depth.

The shaking machining method is a machining method in which a threaded electrode smaller than the diameter of the bottom hole is inserted to the required machining depth. This processing method of gradually changing the amount of shaking can be processed by different processing conditions of rough, medium and fine, so it has the advantage of efficient processing.