4-Jaw Self-Centering Chuck for Wood Lathes Instruction Sheet

1.Parts inventory

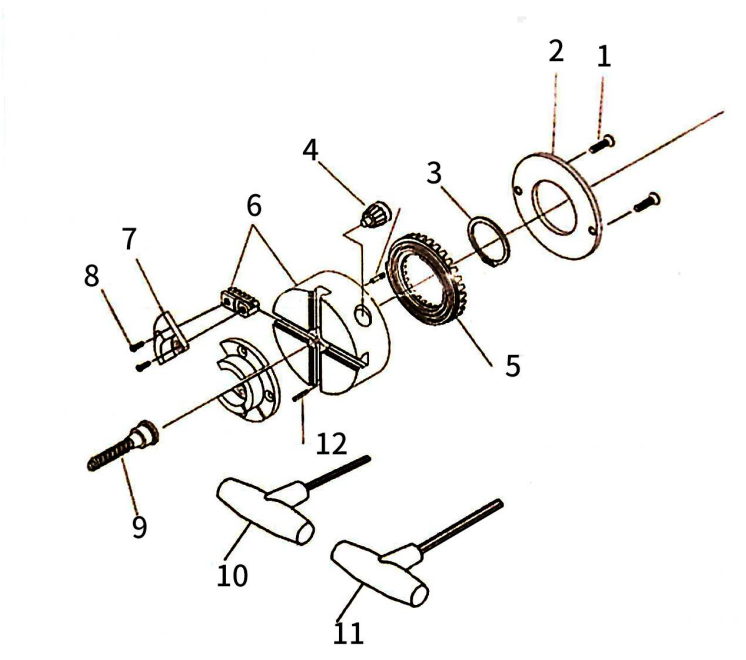

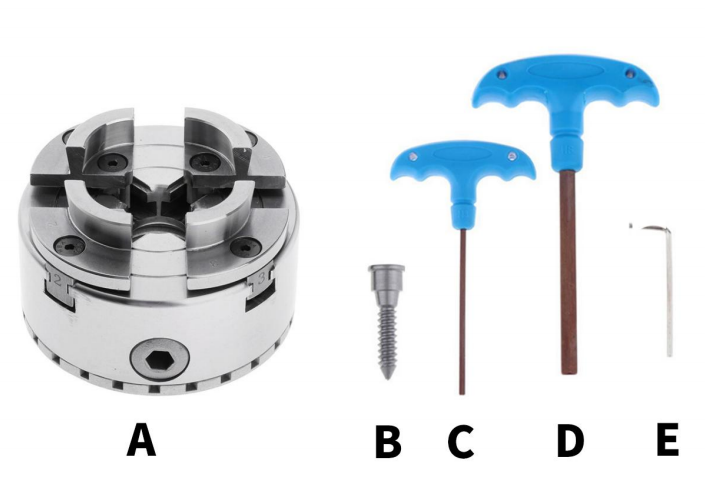

Figure 1 – Contents

A.4-jaw Self-Centering Chuck

B.Wood Screw

C.T-handle hex wrench,3 or 4mm

D.T-handle hex wrench,8 or 10mm

E.Spanner

NOTE 1: Children may climb into plastic bags and suffocate. keep all plastic bags included in packaging out of the reach of children.

NOTE 2: Follow all safely procedures for woodwork-ing when using this chuck.

2.Assembly Instructions

The chuck comes preassembled from the factory. You will need to check that the insert is firmly screwed into the chuck body before mounting on your lathe.

1.Remove the chuck and the accessories from the box.

2.Clean all items thoroughly.

3.Once the insert is secure, screw the assembled chuck onto the lathe spindle.

4.The insert must be firmly seated against the lathe spindle shoulder .

3.Operation Instructions

This chuck’s compact size makes it ideal for use on 12″(300 mm) capacity lathes and

smaller.The jaws are configured for both outside diameter (O.D.)and inside diameter(1.D.)gripping.

A. Opening/Closing Jaws

With the chuck mounted on the lathe,open/ close the chuck jaws so that the workpiece can be placed between the jaws.

1.Insert the workpiece between the jaws.Be sure that the workpiece is seated against the jaw face.

2.Close/open the chuck jaws to securely clamp the workpiece.

3.To remove the workpiece for the chuck,open/close jaws until the workpiece is free.

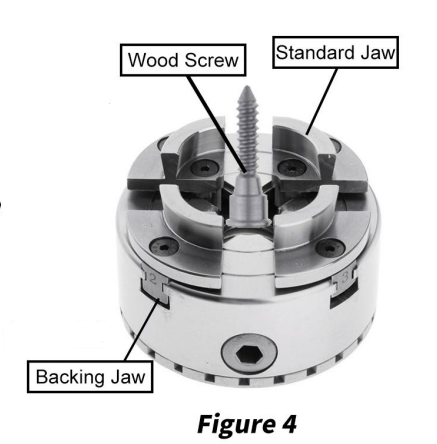

B. Wood Screw Use

This chuck is supplied with a wood screw for use with small,cross-grained pieces.

1.Drill a 7-8 mm diameter hole that is 25 mm deep, in the center of the workpiece.

2. Make sure the workpiece is as round as possible.

3. Mount the wood screw in the chuck with the shoulder of the wood screw clamped between the backing jaws .

4.Screw the workpiece onto the wood screw until it is firmly against the jaws.

5.Unscrew workpiece once machining is completed.

C. Chuck Maintenance

1.To maintain the chuck, spray oil into the scroll and work the jaws through their full range of motion. Do this on a daily basis.

2.Check the chuck for dust build-up in the scrolls and jaws and clean as required.

3.To remove the jaws and backing jaws, the stop pin will need to be removed from the slot of jaw #4. By doing this, the jaws will be able to travel beyond the scroll and then they can be pull out of the slots.

4. To install jaws, first make sure you have jaw #1 going into slot #1 and so on, then turn scroll until all jaws have engaged.Continue turning scroll until the pin hole in slot #4 is visible and then reinsert the stop pin.

4, Parts

1 flat Hd Scr

2 Backing Plate

3 Ext Retaining Ring 50mm

4 Scroll Ring

5 Pinion

6 Backing Jaws W/Chuck Body

7 Chuck Jaws(Qty 4)

8 Taper Head Screw

9 Wood Screw(Special)

10 T-Handle Hex Wrench 3 or 4mm

11 T-Handle Hex Wrench 8 or 10mm

12 Stop Pin

13 Lock Pin